Hovercraft Consultants

Hoverfreight has a division called Hovercraft Consultants and has brought together a team of experienced hovercraft and marine engineers, many have been in the business over 45 years to offer a wide range of knowledge and experience to industry on how to access difficult areas such as swamps and tundra.Unfortunately there many so called experts who write studies but have never have been in the field. Our background is based on the tried and practiced approach of marine engineering because if a ship breaks down mid Atlantic it must be fixed by the crew as no one is going to send a support ship out to fix it.

This approach has meant we have designed and built all the commercially successful Hoverbarges over the last 47 years and our hovercraft experts have built the most used commercial high speed hovercraft.

The Hovercraft and heavy lift Hoverbarges are now over 50 years old with has many applications and the technology can be used from fast military craft to large industrial barges, then down to small industrial hover pads for factories or launching huge concrete caissons.

Hovercraft Consultants unique knowledge is now available:

- engineering studies associated with accessing shallow water sites, swamps, ice, snow and soft ground locations

- moving large loads and crew into remote locations

- accessing amphibious equipment and specialist equipment suppliers

Why Hovercraft Consultants?

Civil engineering, Mining, Oil and Gas companies are all facing greater accessing issues for their remote sites and new regulations has made this become increasingly difficult.The use of Hovercraft technology can resolve many of the issues facing the logistics planner and engineering requirements when accessing difficult sites.

Unfortunately, cost / logistical barriers still remain – remote, inhospitable or environmentally sensitive terrain across which enormous amounts of equipment or crew have to be transported, pushing the costs sky high. This is assuming that traditional methods of transportation are even possible in such terrain.

The answer lies in the use of the well proven Air Cushion Technology (ACT) and associated amphibious solutions. This simple technology based on load over area so that ground pressure can be very low. In many cases environmentally sensitive areas cannot take the weight even of a man walking let along a conventional vehicle. All weather roads are expensive and environmentally damaging whereas the use of hover systems can elevate that issue.

Many specialist support vehicles that have a light footprint can also be used but knowledge of their availability is limited.

This site brings all these elements together.

Background

Hovercraft came commercially available around 50 years ago and at first was considered the possible solution to high speed transport.Like all new inventions whether the car, plane or steam ships it takes roughly 40-50 years from invention to proper commercial use and still applies even still today with the hovercraft technology.

Misunderstanding of the technology often means people think it is only James Bond that will need the hovercraft but its applications are wide and varied and after the initial excitement the industry has stabilized and matured.

The basic concept is simple using load over area to create low pressure. The final pressure required will depend on the application so in the case of a high speed craft such as used for the military or passenger craft a very low pressure less than 0.5psi is preferred. Whereas for slow moving commercial hoverbarges the pressure can be up to 1psi and using a water cushion large concrete caissons can be launched. .

In all these cases the skirt design and the skirt material is critical. Some companies have tried to use PVC and conveyor belting but with little long term success.

Our team of hovercraft experts can advise on this critical area with engineers who have been involved from the earliest conception, with practical experience not so called experts who have never worked in the field.

If the skirt is designed wrong with incorrect materials two things happen 1) it may not lift 2) the material will fail.

How does it work?

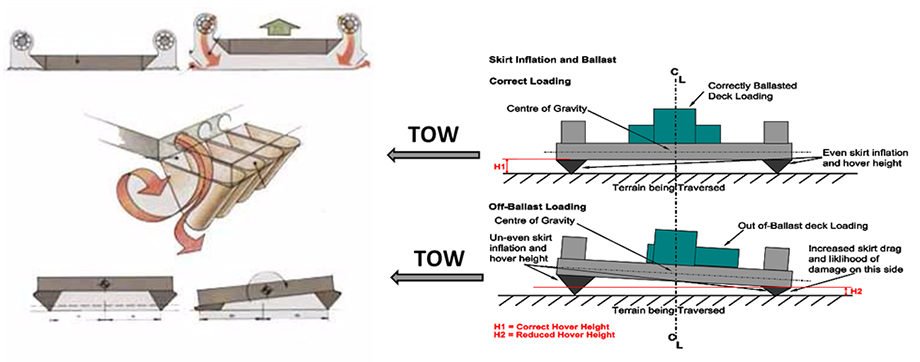

A flexible seal around the periphery of the craft retains the air cushion so once primed the craft will lift off the ground. The design of the skirt system is critcal for an efficient lift and flexibility.

The skirt design will give the desired hover height and add stability to the craft as the centre of pressure shifts.

Generally there are two types of craft the high speed passenger or low speed commercial craft for heavy lift.

Heavy Lift:

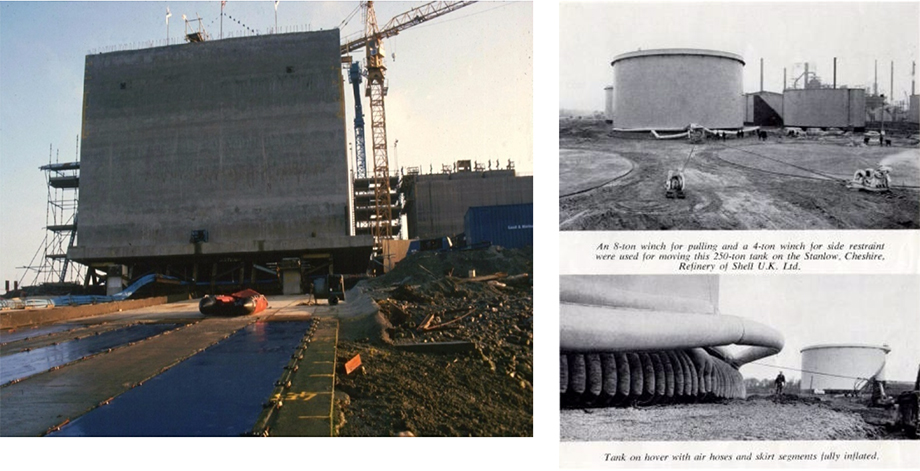

In addition using the skirts to retain a higher pressure loads such as 3000t-6000t concrete caissons have been launched on water cushion or moving an oil storage tank on an air cushion.

So whether it is people or caissons the hovercraft system can be adapted to suit a wide range of situations.

Using Hovercraft technology when there is no infrastructure with access and/or environmental issues can save a great deal of money. It takes a major step to think outside of the box but the saving can be huge for example building a process plant in a remote coastal facility with limited road access may require building a camp large enough to house thousands of workers that will require rotating on a regular basis.

Whereas using an existing shipyard to produce the plant in shrink wrapped modules that can be delivered to site with hovercraft technology could save 15-20% of the cost and maybe even halve the time involved reducing the team on site to the minimum.

Building roads and new docks that may not be required after construction can be a costly exercise especially if the contract labour has no incentive to complete the work on time.